The functioning of construction equipment is highly dependent on fuel injection pumps, which are among the least considered parts when undertaking project efficiency planning, making Construction Equipment Fuel Injection Tips especially valuable for site managers. Bulldozers, generators, excavators, and loaders are just a few examples of heavy machinery powered by diesel engines on a job site.

The relevance of Fuel Injection Pumps.

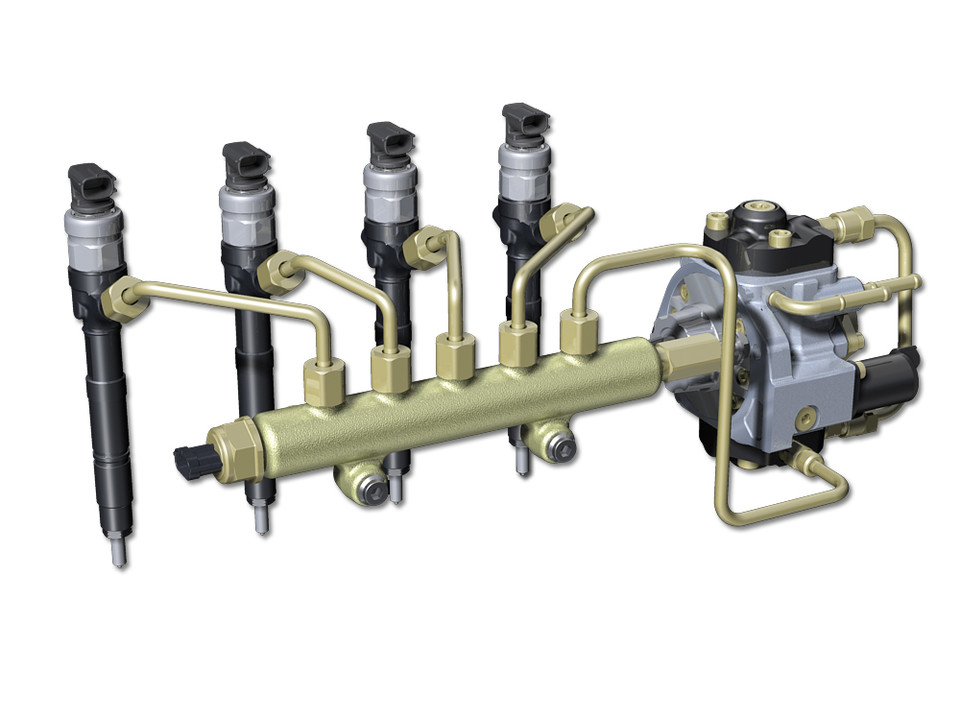

The fuel injection pumps have the role of ensuring that diesel is delivered into the combustion chamber of an engine at the right time and pressure. The more efficient the delivery is, the more complete and efficient the combustion process. A properly operating system will make sure all the fuel is used in mechanical power and does not go to waste. Late timing, damaged parts or inefficient delivery will lead to increased fuel consumption, reduced engine power and emissions. Considering that fuel may account for a large percentage of operating costs in construction sites, any slight increase in the efficiency of injection systems can result in significant cost reductions in the long term.

The Real Price of Inefficient Fuel Systems.

The inefficient fuel injection systems will not only raise fuel expenses, but also adversely impact the performance and durability of the equipment. Bad pumps or injectors can increase the fuel use by 10-20 per cent and lead to lower torque production, which causes the machinery to work harder to accomplish the same task. Poor injection combustion can enhance the rate of engine wear and maintenance expenses are increased. These inefficiencies are also likely to drive up machine idle time and schedule on busy sites, which exacerbates labour expenses and project-milestone delays. The dust, heat, and debris prevalent in the construction sites also mean that fuel systems are tested further, which necessitates a proactive optimisation of the system to regulate the operating costs.

The way Modern Injection Technology enhances Performance.

Fuel injection has revolutionised the performance of a diesel engine. Variable-displacement pumps and high-pressure common rail systems ensure constant pressure and can be electronically controlled regarding the time of injection. This leads to the finer atomization of fuel and further combustion leading to decreased fuel usage, lower emissions and increased power available. Modern systems also enhance throttle response and cold starts giving it better performance on a large variety of conditions. Although the newer technology is associated with a higher initial investment, the construction operations are often able to pay even faster due to reduced fuel costs and increased uptime.

Planned Maintenance Strategies that Work.

No matter how good fuel injection technology is, it will not be able to achieve its maximum efficiency unless it is well maintained:

Quality Fuel: One of the major causes of pump and injector failure is contaminated fuel. Sensitive system components are also safeguarded by clean fuel, quality filtration and strict fuel handling practices.

Periodical Checks: Wear and deposits wear-out injector and pump performance. Regular inspections- at best of 500 running hours- allow detection of problems in time before they develop into breakdowns.

Proactive Replacement: It can be expensive to wait until a component has failed. Maintenance ensures high uptime by the replacement of worn seals, nozzles, or sensors before they break down, thereby minimising the cost of emergency repairs.

Measure Performance Data: Telematics systems on the new machines can measure the trends of fuel consumption in real time. Unexpected consumption changes frequently indicate the emergence of injection problems and therefore early response can be achieved and more severe failures can be prevented.